- CALL US

- +1 (647) 646-6572

FREE SHIPPING

FREE SHIPPING

PREMIUM DELIVERY

PREMIUM DELIVERY

FREE SHIPPING

FREE SHIPPING

PREMIUM DELIVERY

PREMIUM DELIVERY

$374.99

ETA: 5 to 8 Business days

Applications:

Operating conditions:

Motor and Pump:

.

Applications:

Operating conditions:

Motor and Pump:

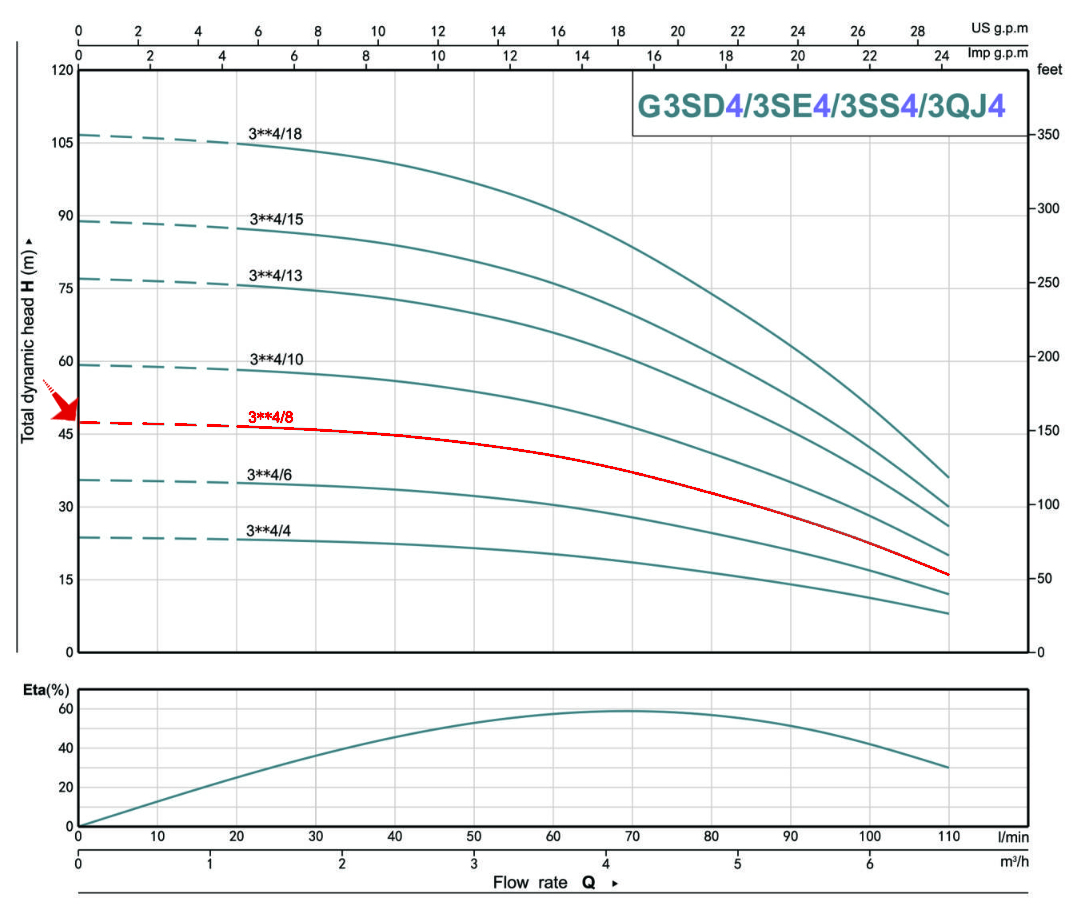

| MODEL | P2 | DELIVERY N = 3450 1/min | ||||||||||||||

| 1~

220V |

KW | HP | Q | m3/h | 0 | 0.6 | 1.2 | 1.8 | 2.4 | 3.0 | 3.6 | 4.2 | 4.8 | 5.4 | 6.0 | 6.6 |

| l/min | 0 | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 110 | ||||

| 3SD M4/8 | 0.55 | 0.75 | H (m) | 48 | 47 | 47 | 46 | 45 | 43 | 41 | 37 | 33 | 28 | 23 | 16 | |

| Model | DN | Dimension(inch) | Weight(lbs) | ||||||||

| 1~

110V/220V |

P | M(s) | M(t) | T(s) | T(t) | P | M(s) | M(t) | T(s) | T(t) | |

| 3SD M4/8 | 1″/1* 0.25″/1* 0.5″ | 17.5 | 14.5 | 13.3 | 32 | 30.8 | 4 | 14.1 | 12.3 | 18 | 16.3 |

| Components | Material |

| Pump external casing | AISI 304 SS |

| Delivery casing | Cast-Cu ASTM C85500 |

| Suction lantern | Cast-Cu ASTM C85500 |

| Diffuser | Plastic.PC |

| Impeller | Plastic.POM |

| Shaft | AISI 304 SS |

| Shaft coupling | AISI 304 SS |

| Wear ring | AISI 304 SS |

| Motor external casing | AISI 304 SS |

| Top cover | Cast-Cu ASTM C85500 Cast-iron ASTM NO.30 |

| Bottom support | AISI 304 SS |

| Mechanical seal | Special seal for deep well(Graphite-Ceramic/TC) |

| Shaft | AISI 303 SS-ASTM 1045/5140 |

| Seal lubricant oil | Oil for food machinery and pharmaceutic use. |

Also submersible pumps shaft is connected to the gas separator or the protector by a mechanical coupling at the bottom of the pump and Fluids enter the pump through an intake screen and are lifted by the pump stages and other parts include the radial bearings (bushings) distributed along the length of the shaft providing radial support to the pump shaft, also An optional thrust bearing takes up part of the axial forces arising in the pump but most of those forces are absorbed by the protector’s thrust bearing.

| Weight | 29 lbs |

|---|---|

| Dimensions | 30 × 8 × 5 in |

| Choose Voltage | 110V, 220V |

| AC Voltage | 110-115 Volts, 110/220 Dual, 208-220 Volts |

| Horse Power AC | 0.75 HP |

| Submersible Pump Size | 3" |

| HP Submersible pump | 0.75 HP |

| Material Submersible pump | Stainless Steel 304 |

| Pump Outlet | 1 1/4" |

| Phase | Single Phase |

Copyright © 2025 Canada Pump Center. All Rights Reserved